Dr. Kristine Aadland

Smile Design Expert

Watch Masterclass

Scan

Capture Scan Data

Scan

Capture Scan Data

Successful smile design starts good data collection. Intraoral scans are taken twice: once during the initial consultation and again after the teeth have been prepped.

Compatible Scanners

- 3Shape

- Medit

- Carestream

- CEREC

- And more!

Learn From the Best

Fill out the form to access all SprintRay Masterclass content for free.

Plan

Submit to Cloud Design

Plan

Submit to Cloud Design

After initial scans, upload data and treatment information via SprintRay Cloud Design portal. Live chat with the design team to ensure your treatment vision is met.

Smile Design

- $20 fee per designed tooth

- Shell temps included

- 1 business day turnaround

Print and Process

Print and Process

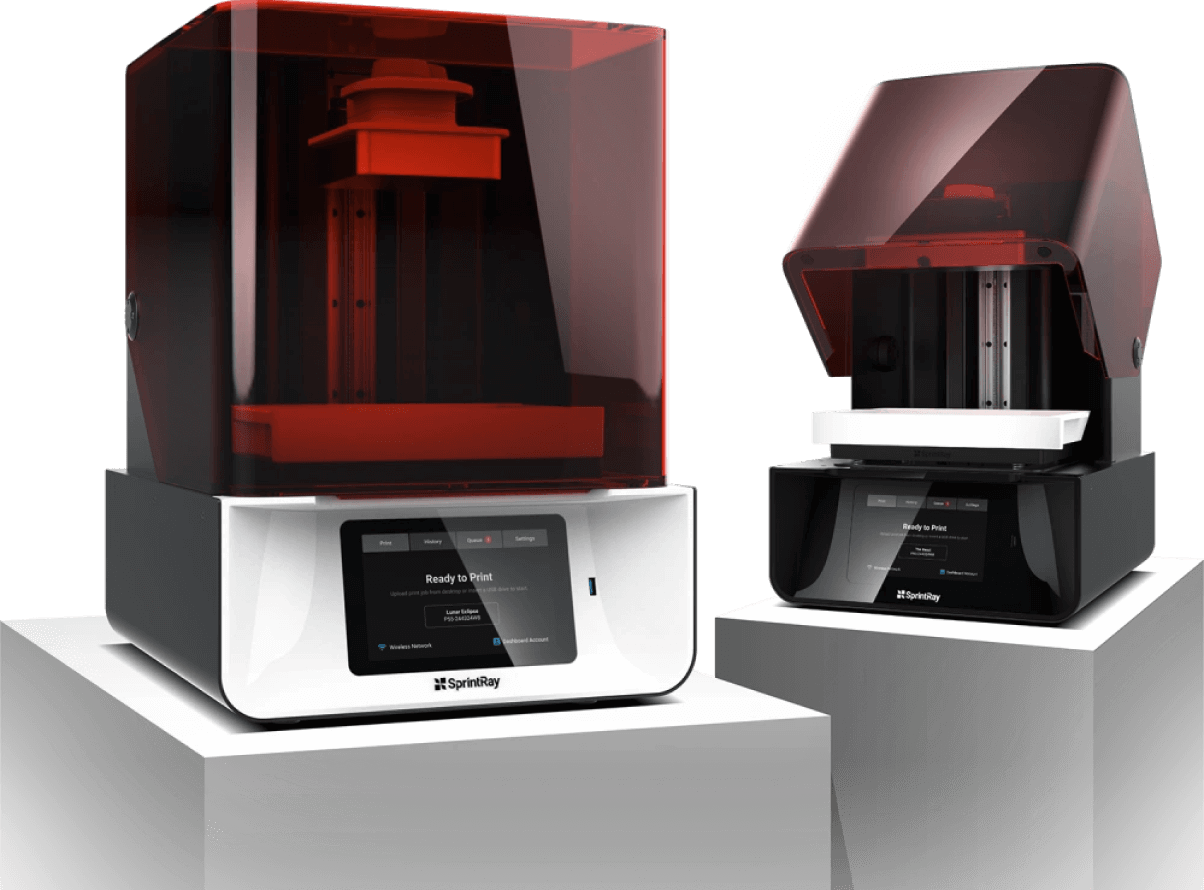

Send Cloud Design files to your SprintRay Pro 3D printer. Wash and post-cure shell temps and waxups to use for presentation. After the patient has been prepped, use RayWare to close & base intraoral scans and 3D print an accurate working model for preparing final veneers.

Frictionless Printing Workflow

- 3D print shell temps and waxup model

- Use RayWare to base intraoral scans

- 3D print working model in just 20 minutes

Fabrication, Simplified

From design to print to patient delivery, SprintRay delivers the promise of digital dentistry by offering a fully-integrated 3D printing solution. Cut long lead times, learning curves, and costs associated with traditional lab and CAD/CAM production by introducing the Frictionless Workflow into your practice with the SprintRay ecosystem.

Process for Delivery

Clinical Preparation

Process for Delivery

Clinical Preparation

Remove supports and briefly polish shell temps with a handpiece to give them a lifelike surface. Waxups and working models require little to no processing.

Preparation Tips

- Follow resin post-processing instructions closely

- Remove supports and polish surface

- Models require little to no processing

Deliver

Deliver Treatment

Deliver

Deliver Treatment

Use shell temps and waxup model to communicate roadmap to your patient. Prep the patient, re-scan, and 3D print your working model. Mill final veneers, stain and glaze, and deliver.

Benefits of 3D Printing for Smile Design

- Fabricate shell temps for just a few dollars

- 3D print working model for perfect fitment

- Improve communication with patient

Your 3D Printing ROI Report

Profit & Cost with SprintRay

*Cost based on total equipment sale financed for 24 months at 0% APR.

By Taking advantage of SprintRay 3D printing, you could net $ in your first year!

3D Printing Vs Outsourcing

By outsourcing production, producing of Shell Temps per year would cost you . 3D printing those parts with SprintRay would only cost you !

Monthly Production Cost

With SprintRay 3D printing, you could save your patients of wait time between appointments in your first year.