Dr. Brandon Owen

Worldwide Leader in Indirect Bonding

Start Masterclass

Scan

Capture Data

Scan

Capture Data

Every procedure starts with solid data collection. Capture intraoral scan data and make sure to wrap the incisors for maximum accuracy.

Compatible Scanners

- 3Shape

- Medit

- Carestream

- CEREC

- And more!

Plan

Treatment Plan

Plan

Treatment Plan

Take your scan data and turn it into a printable design. Dr. Owen uses DIBS AI software to create IDB trays.

Total Treatment Control

- Custom braces

- Predictable movement

- Great fit every time

Print and Process

Print and Process

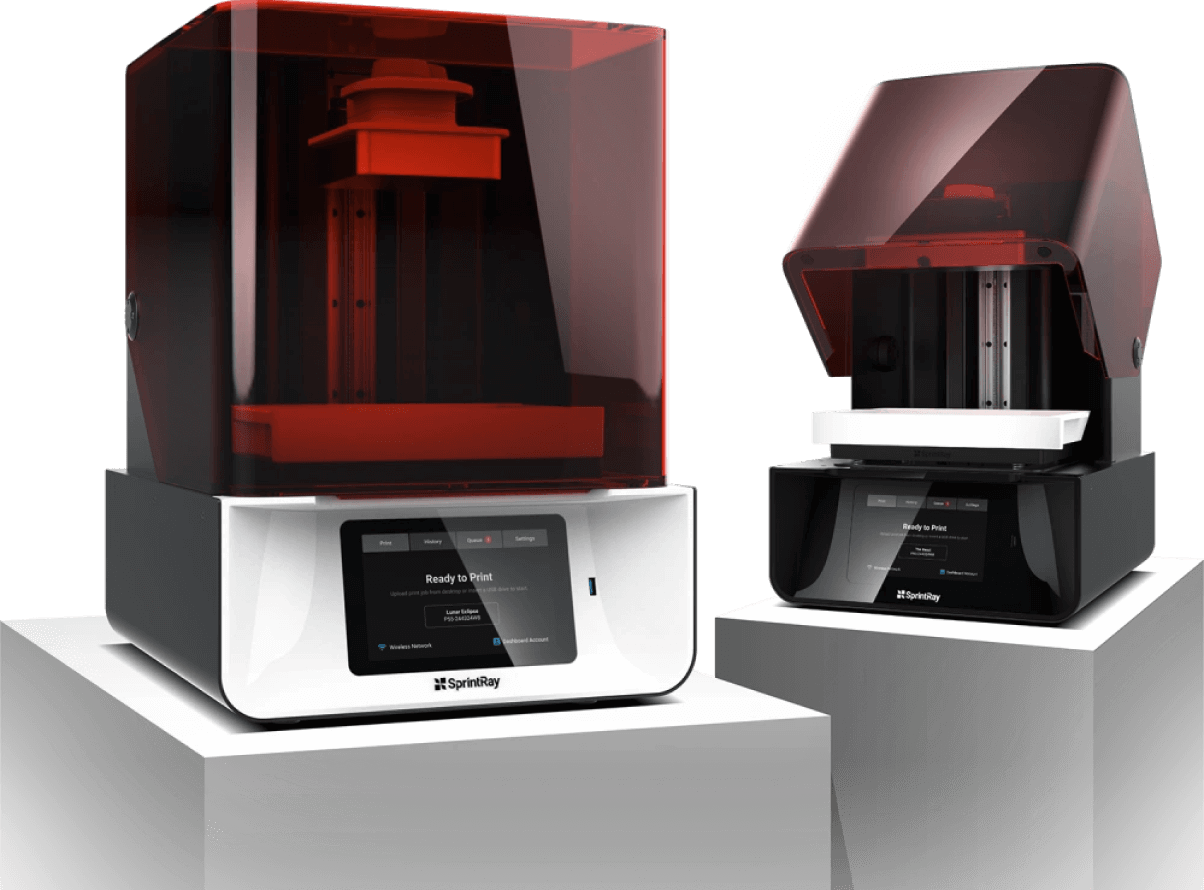

Export your IDB tray to RayWare and 3D print in around 40 minutes. Wash and post-cure your trays for FDA compatibility and optimal mechanical performance.

Frictionless Printing Workflow

- Rapid prints with SprintRay Pro

- One-touch wash with Pro Wash

- FDA-compliant outputs with Pro Cure

Fabrication, Simplified

From design to print to patient delivery, SprintRay delivers the promise of digital dentistry by offering a fully-integrated 3D printing solution. Cut long lead times, learning curves, and costs associated with traditional lab and CAD/CAM production by introducing the Frictionless Workflow into your practice with the SprintRay ecosystem.

Process for Delivery

Clinical Preparation

Process for Delivery

Clinical Preparation

Place the brackets in each IDB tray arch and preload them with adhesive. Make sure to store trays in a dark box to avoid premature curing.

Preparation Tips

- Use forceps to load brackets

- Pre-apply adhesive for max speed

- Keep trays in dark box until placement

Deliver

Placement

Deliver

Placement

Once the tray has been placed on the arch, apply buckle pressure and cure with handheld curing light. Repeat across the arch, then peel the tray away.

Benefits of Indirect Bonding

- Full control over placement

- Delegate process to staff

- Individuated tooth movement